Reinforced Earth has developed several solutions to design and build large precast concrete box bridge structures. Our customized solutions are recognized by owners, engineers and builders alike.

The TechBox™ innovation

This Reinforced Earth solution satisfies our customers’ need for a speedy and durable alternative to building large cast-in-place standalone or multi-cell box culvert alternatives. TechBox™ is ideally suited to having clearance envelops of ≥ 5m x 3m.

Typical applications for TechBox™ include cut-and-cover box structures as single or multi-span for direct support and thruway for vehicles & railway (including heavy rail), pedestrian and animal crossings, and waterways.

The TechBox™ design approach

Our structural and geotechnical design approach considers soil-structure interaction, and all peripheral characteristics of the structure’s size, purpose and setting. Reinforced Earth engineers analyze subsurface and backfill planning, the sequence of installation and service performance requirements. By modeling the in-service structure through FEM analysis, our bridge specialists establish reliable elasto-plastic soil models in determining acceptable soil stiffness and elasticity, and then design the structural precast elements around these soil-structure models.

We combine the soil behavior model with optimized thin and flexible articulated structural components which result in a highly predictable and stable design for your structure. The result:

- Cost effectiveness: overall installed costs is at par or lower compared to conventional methods.

- Time savings: the standardized method to install modular units dramatically reduce construction time.

- Technical quality: factory controlled production of wall panels and over-bridging slabs ensures best quality.

- Sustainability: optimized material content using thin sections and backfill as a structural element reduces consumption of materials.

- Safety in mind: using highly engineered precast elements, it is easiest to organize safety at jobsites through standardized procedures.

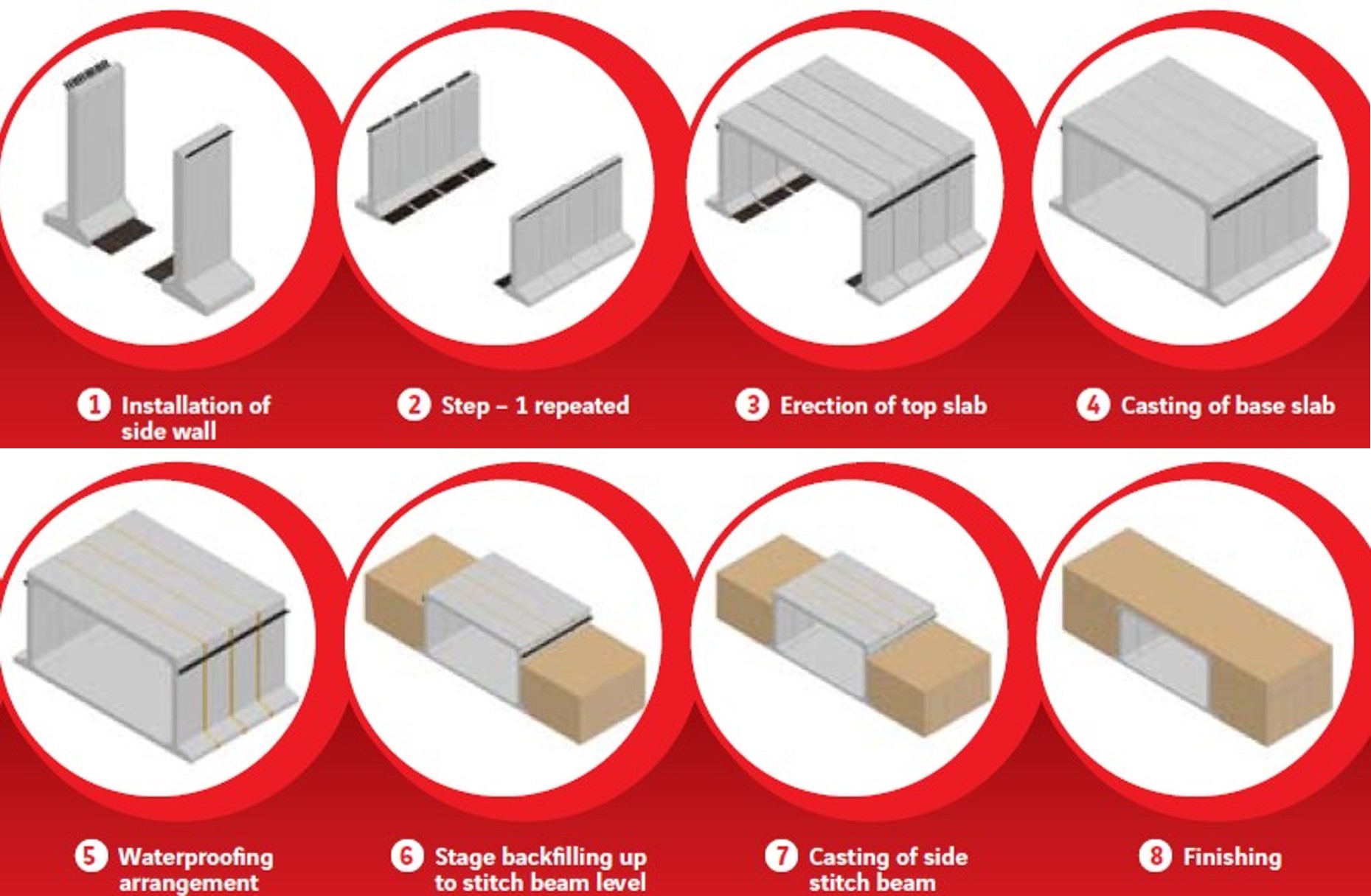

TechBox™ construction procedure

- Installation and alignment of initial precast segmental, full-height side wall panels.

- Continuation of installing full-height precast side walls.

- Installation of segmental over-bridging (top slab units).

- Cast in-situ base slab (if required).

- Application of joint treatment.

- Stage 1 backfilling (prior to side stich application).

- In-situ casting of side stitch (connecting side walls to top slabs).

- Stage 2 backfilling (completion and finishing).

MSE Wall alternative for box-bridges

The versatility of Reinforced Earth® MSE walls lends itself to building box bridges. These walls are often designed in similar fashion to road and rail bridge abutments with adjoining MSE wing walls to form box bridge structures.

TechWall™ and T-Wall® alternative for box-bridges

In some circumstances involving very wide span openings, a custom designed TechWall™ counterfort wall or T-Wall® solution may be adapted to create a box bridge, typically requiring long-span over-bridging elements.

Architectural finish

We have a wide array of architectural finish options available, allowing architects to customize structures and to specify facing elements with an attractive rendering.

Related solutions

Reinforced Earth®

Reinforced Earth®

Our flagship technique, Reinforced Earth®, is based on the principle of the friction between soil and reinforcements creating a permanent and predictable bond. At the origin of all mechanically stabilized earth (MSE) walls on the market today, we are continuously perfecting this ingenious technique.

TechWall™

TechWall™

A precast retaining wall system, TechWall™ combines the advantages of counterfort with the quality and effectiveness of precast concrete. A great fit for sites with soil bearing capacities allowing for shallow foundations, TechWall™ can also be combined with piling solutions to accommodate different types of soil. Sustainable, cost-effective, and quick to install, TechWall™ may just be the ideal solution for your project needs.